Yamazaki Bulk System

Product Catalog

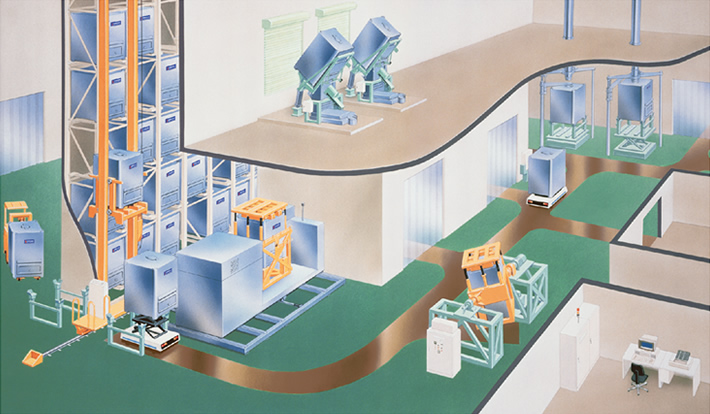

Yamazaki Bulk System in various industries Powder-handling processes in the following fields including storing, filling, mixing, and discharging;

- Watch Yamazaki Bulk System in action in the video.

◎Food industry

◎Pharmaceutical products

◎Chemical field (Companies that handle powders for rechargeable batteries)

◎Semiconductor industry Powder-handling processes in the following fields including storing,filling,mixing,and discharging;

Tote Bin (Container for powders)

Tote Bin can be used to store, transport, and mix powders. It is made of stainless steel. Finishing can be tailored depending on the use of the container.

Features

- The discharge opening is wide enough to enable smooth discharge of powders without causing consolidation.

- The boxed-shape container can be conveniently stored.

- The sealed structure retains the quality of the contents.

- The capacity can be tailored from 800 liters to 3,100 liters.

Tilting Equipment (Discharger)

Tilting equipment is for discharging powders from the Tote Bin.

Powders are never dispersed as it discharges in a sealed condition.

Discharge Process

- Set the Tote Bin.

- Tilt the equipment by cylinders and tightly attach the discharge opening of the Tote Bin to the hopper of the discharger.

- Once you open the discharge opening of the Tote Bin using a special tool, the powders are discharged.

Cap Container

Powders can be easily discharged by raising the discharge valves using cylinders.

Features

- Powders can be easily discharged by controlling the discharge valves.

- The discharge process can be stopped halfway by raising or lowering the discharge valves.

- A predetermined amount of powders can be discharged used in combination with a gauge.

Container

This container is for powders, tablets, and liquid. The container is made of stainless steel or aluminum. Capacity, dimensions, and specifications can be customized in accordance with your requests.

Container Doser

The Container Doser provides an automatic addition of powders to containers.

- The top cover of the container is automatically removed.

- The filling nozzle and the container intake are connected as the table lifter rises.

- The powders are discharged into the container when the valves open.

- The valves are closed when the powders are filled to the predetermined weight.

- The top cover of the container is automatically refitted as the table lifter lowers.

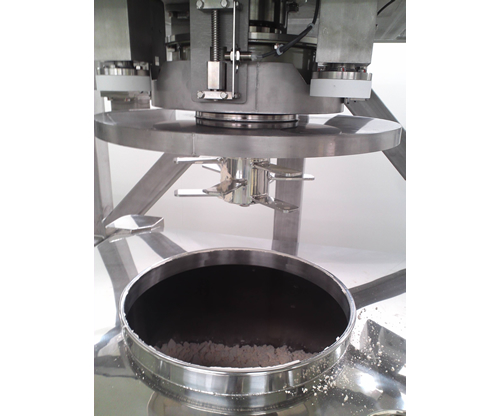

Container Tumbler

Container (Tote Bin) can be used as a mixer when set in the container tumbler. You can set the container by means of forklifts, conveyors, transfer vehicles, and containers on casters.

Features

- You can handle different types of powders simply by replacing the container.

- The container setting method frees you from cleaning of the container tumbler.

Container Tumbler with Impellers

17. Attach the motor to the body of the container tumbler and set up the top cover of the container with detachable impellers. When the container is clamped to the container tumbler, the motor and the top cover is connected to rotate the impellers and mix powders in the container.

- The impellers are easy to clean as they are set up to the top cover.

- The container tumbler can be tailored to accommodate your containers. (100 L to 2000 L)

- A hydraulic sprayer can also be installed.

Super Container Tumbler

The Super Container Tumbler is a powder mixer. It mixes and uniformizes powders in the container in a short time by revolving the container on three-dimensional directions. The mixing completes in one-third of the time comparing with the Container Tumbler (in-house comparison).

- You can handle different types of powders simply by replacing the container.

- The container setting method frees you from cleaning of the container tumbler.

- The optimal rotation settings enable shorter mixing time.

- The container tumbler can be tailored to accommodate your containers. (100 L to 2000 L)

- Patented

Cleaner

Cleans and dries the interiors and exteriors of used containers (Tote Bins). Can be customized according to the required cleaning capability (unit/ time).

One Compartment Cleaner

Capacity: 1 unit for 40 to 60 minutes

Use: Cleaning and hot-air drying of interior and exterior of containers

Air Vibrator

Offers over 100 models to choose from for a variety of applications.

Rotating Type

Ball type (K series), Roller type (DAR and R series), and Turbine type (GT and T series)

Piston Type

FP and FPLF series and VTL series

Oil-free Series

Turbine-type GT series and Piston-type FPLF and FAL series

* The oil-free series are well praised by the customers in the food, chemical, pharmaceutical, and semiconductor industries.

Container Lifter

Used for transporting a container and setting it in a raised location.

Can be tailored in accordance with the container specifications.

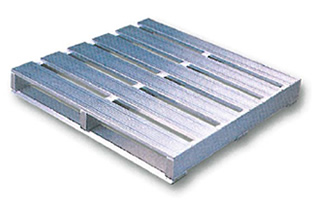

Aluminum Pallet

Dimensions and the form can be customized without limits.

Features

- Lighter than wooden pallets by 25% and resin pallets by 50%

- Cleaning and disinfection are easy. Generates no scraps and no static electricity.

- Non-flammable and recyclable. Low production costs as no dies are needed.